Liquid Distributor

The distributors ensure a uniform flow of the liquid to the packing. Depending on the type of packing, the following values can be achieved.

Dropping point density: 50-250 TS / m2

Liquid load: 0.1-200 m3 / m2 h

The liquid distributors are aligned exactly on a holding grid or on column supports.

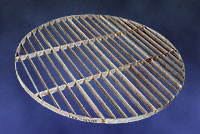

Liquid Collector

The liquid collectors have the task of catching as much as 100% of the liquid. Vane collectors with a low pressure drop have proven to be successful. Chimney collectors are used when the liquid has been completely removed or high liquid loads are present.

Liquid collector with ring channel

For smaller column diameters, the liquid collector can be supplied in one piece with the ring channel and installed directly in the column on a support ring.

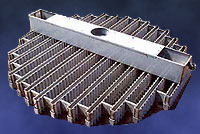

Support Grid for Packings

The support grids are below the packings. The at the bottom jagged sheets result in a uniform flow of the liquid from the grid. All internals are delivered segmented for larger column diameters adapted to the existing manhole.

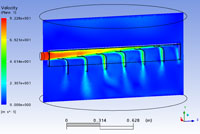

BE.ST Gas Inlet Systems

An uneven flow in reactors, columns or heat exchangers can continue over the entire height. The performance drops dramatically. With a specially tuned gas inlet systems this is avoided. E. g. in reactor beds the upper area can be used optimal and the reactors can thus be built smaller and expensive catalyst is saved.

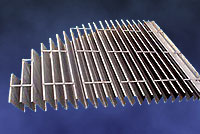

Support Grid for Random Packings

The support grids for packing are matched to the size of the packing and are characterized by a very good stability and a low pressure loss.

Liquid Distributor with Spray Nozzle

Here, the liquid is distributed with pre-pressure via spray nozzles on the packings.

Ringkanal für Flashsysteme

If there is an evaporation of the liquid at the inlet, the vapor content must be distributed evenly into the column. This can be done by feeding into the liquid ring channel or via a special flashbox.